Ball Screw Assemblies

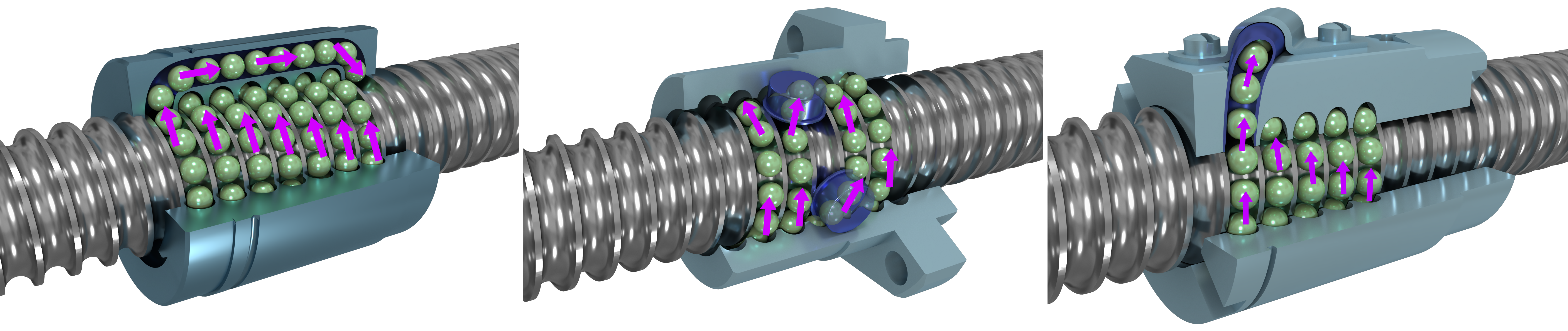

Thomson ball screw assemblies consist of a ball screw, a ball nut with recirculating ball bearings and end supports for mounting. The interface between the screw and the nut is made by ball bearings that roll in matching forms in the ball screw and ball nut. The load on the ball screw is distributed over a large number of ball bearings so that each ball is subjected to a relatively low load. Because of the rolling element design, ball screw assemblies have a very low coefficient of friction, which equates to highly efficient mechanics.