DOWNERS GROVE, IL – Thomson Industries, Inc., a leading manufacturer of linear motion control solutions, has upgraded its online sizing and selection tool, making it easier than ever for motion system designers to optimize their linear systems. Improvements include an interactive application matching grid, enhanced system visualization, increased flexibility in adding accessories, more tailored vendor recommendations and a greater ability to share bills of materials.

"Prepackaged linear systems provide significant advantages in performance, maintenance and cost, but success depends on how closely they match application requirements. We are constantly improving our sizing and selection tools to make linear system configuration faster and easier. With this latest upgrade, we believe we now have the most reliable, accurate and efficient linear unit optimization tool in the industry," said Hans Dahlen, Product Line Manager - Systems at Thomson.

Thomson has made significant upgrades to its linear unit sizing and selection tool, which include an intuitive graphical interface that displays which Thomson products match user-provided application parameters.

The Thomson selector tool automates the selection and sizing process for linear systems, including shafts, lead screws, and guide and carriage configurations. Users can configure these components online following a simple three-step process in which they enter motion parameters such as stroke, speed and distance; load parameters such as weight and force; and then choose from options that fit their application requirements.

"As users enter values at each step, they receive immediate, graphical feedback on products that are available to meet their specifications. If they make a change later in the process, they don’t need to start over. The tool narrows the options to a handful of ideal unit configurations, not tens or hundreds,” explained Dahlen.

Accommodating a Wide Range of Complexity

Advanced algorithms built into the upgraded tool can accommodate a wide range of application complexities. They can show the immediate impact of small adjustments, like the need for an additional carriage when load increases, or can guide users in exploring how small changes in moment load can affect system performance. Once the user enters all motion parameters, the tool generates a model that provides the expected lifespan and price.

The following are among the key new features of the upgraded tool:

- Availability Grid: As users input application requirements, the tool instantly identifies which Thomson components match their choices. If a matching system isn’t immediately available, users can drill down to explore alternatives, minimizing the risk of project delays.

- Visual Selection Process: The enhanced tool includes more visual aids, such as pictures, 2D diagrams, and overlays showing sensor kit placement during the sizing and selection process, making it easier for users to understand their choices.

- Accessory Flexibility: Users now have greater options when adding accessories, such as base part protection for washdowns, external clamping mounts and sensor mount locations. The tool shows only accessories that match the user’s application, ensuring fully customized designs.

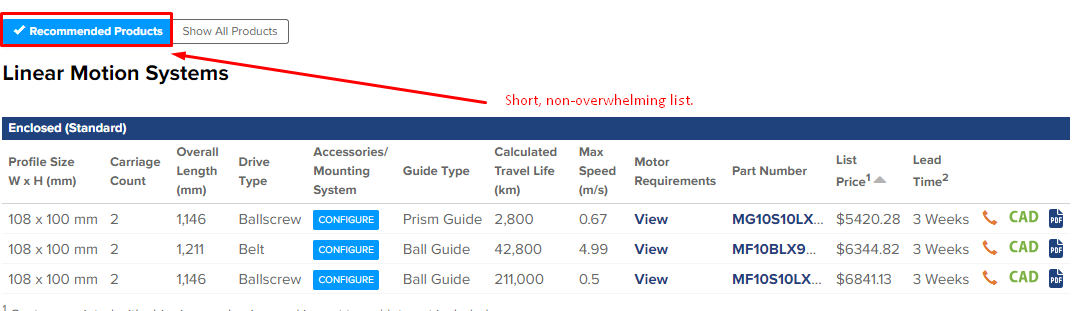

- More Focused Recommendations: The tool’s improved algorithms provide a concise list of product recommendations that align with the user’s application needs, reducing information overload and simplifying decision making.

- Shareable Bill of Materials: After finalizing their selections, users can generate a bill of materials that includes a shareable link for easy collaboration with project stakeholders.

By reducing design time and improving the precision of component selection, the upgraded Thomson linear unit sizing and selection tool ensures users that they can quickly and accurately visualize changes and align their specifications with project requirements.

Where some linear unit sizing and selection tools may require the user to sort through tens or hundreds of options, the new Thomson tool's application configuration calculations return only a handful of desirable options.

The next-generation Thomson product sizing and selection tool is available now at Thomson® Linear Motion Systems.

About Thomson Industries, Inc.

With more than 75 years of achievement in motion control innovation and quality, Thomson is the industry’s premier producer of Linear Actuators, Linear Ball Bushing® Bearings, Profile Rail Linear Guides, 60 Case® LinearRace® Shafting, Ground and Rolled Ball Screws, Screw Jacks, Linear Systems, and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945 and has set the standard ever since with an unsurpassed set of linear motion control solutions serving global aerospace and defense, medical and health, factory automation, food processing, and mobile off-highway markets. Thomson, a brand of U.S.-based Regal Rexnord Corporation, has facilities in North America, Europe and Asia with more than 2000 distributor locations around the world. For more information Thomson Industries, Inc., 2400 Curtiss Street, Downers Grove, IL 60515; 1-540-633-3549; 1- 540-633-0294 (fax); Thomson@regalrexnord.com; www.thomsonlinear.com.